The pavilion has been developed and realised in collaboration between the organizers of WCTE 2023, master’s students and teachers at the Oslo School of Architecture and Design (AHO), Norwegian engineering and architectural companies, and Norwegian material suppliers and manufacturers.

The pavilion’s concept and design have been developed as part of a master studio course at AHO.

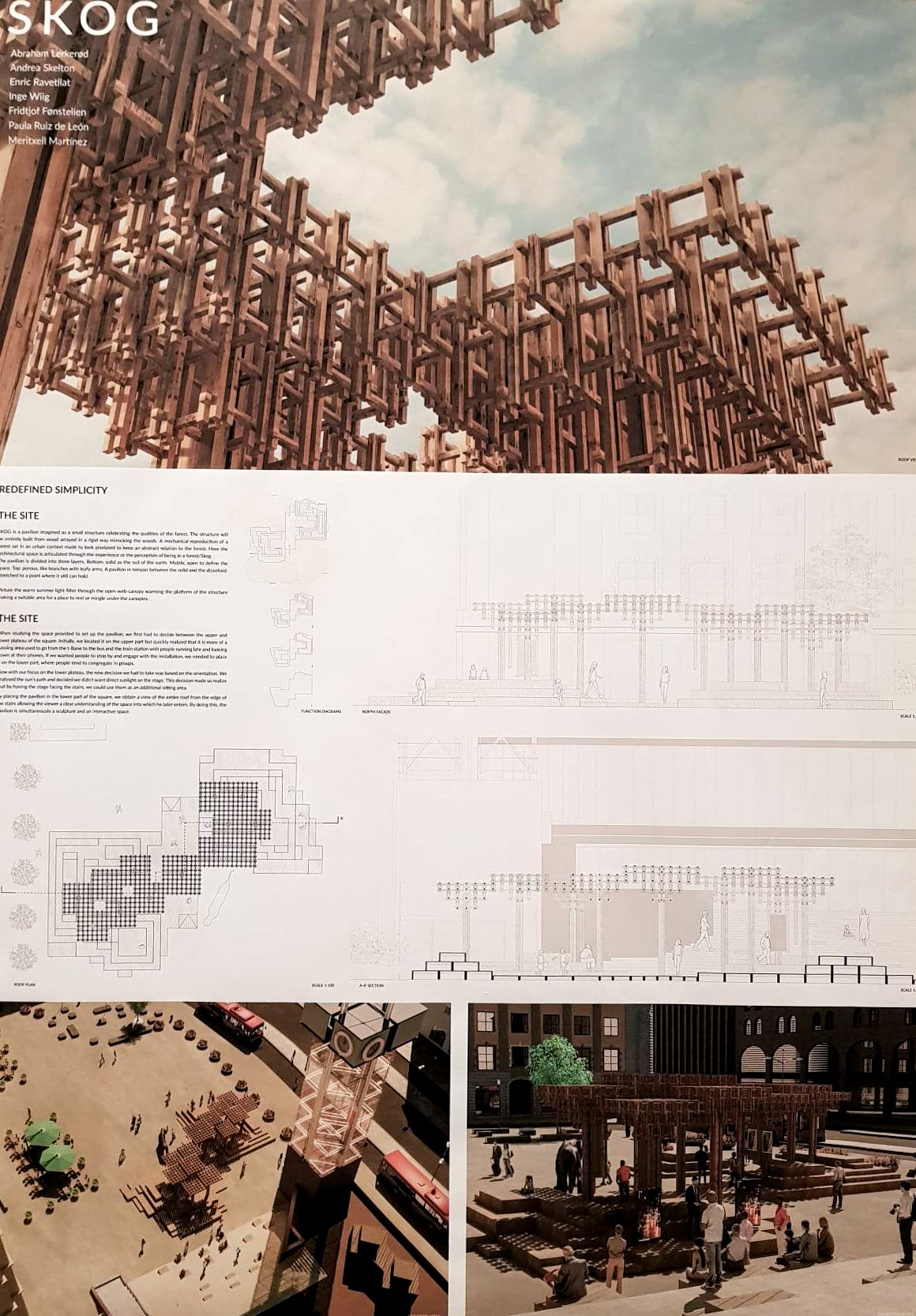

While the previous Timber Studio courses at AHO have focused on appealing and appropriate architecture, flexible layouts, sound construction and design for disassembly, this course dived deeper into both ends of circular design: the materials’ provenience and the construction’s afterlife.

Disregarded materials became our “Re:Sources”: waste wood found at recycling stations, cut-outs from CLT production, parts directly rescued from obsolete buildings, worn out pallets and excess materials from other projects have been joined into new construction members in 1:1 mock-ups. The students have explored the materials’ poetic and conceptual potential, their constructive capacity and the role of various joining options.

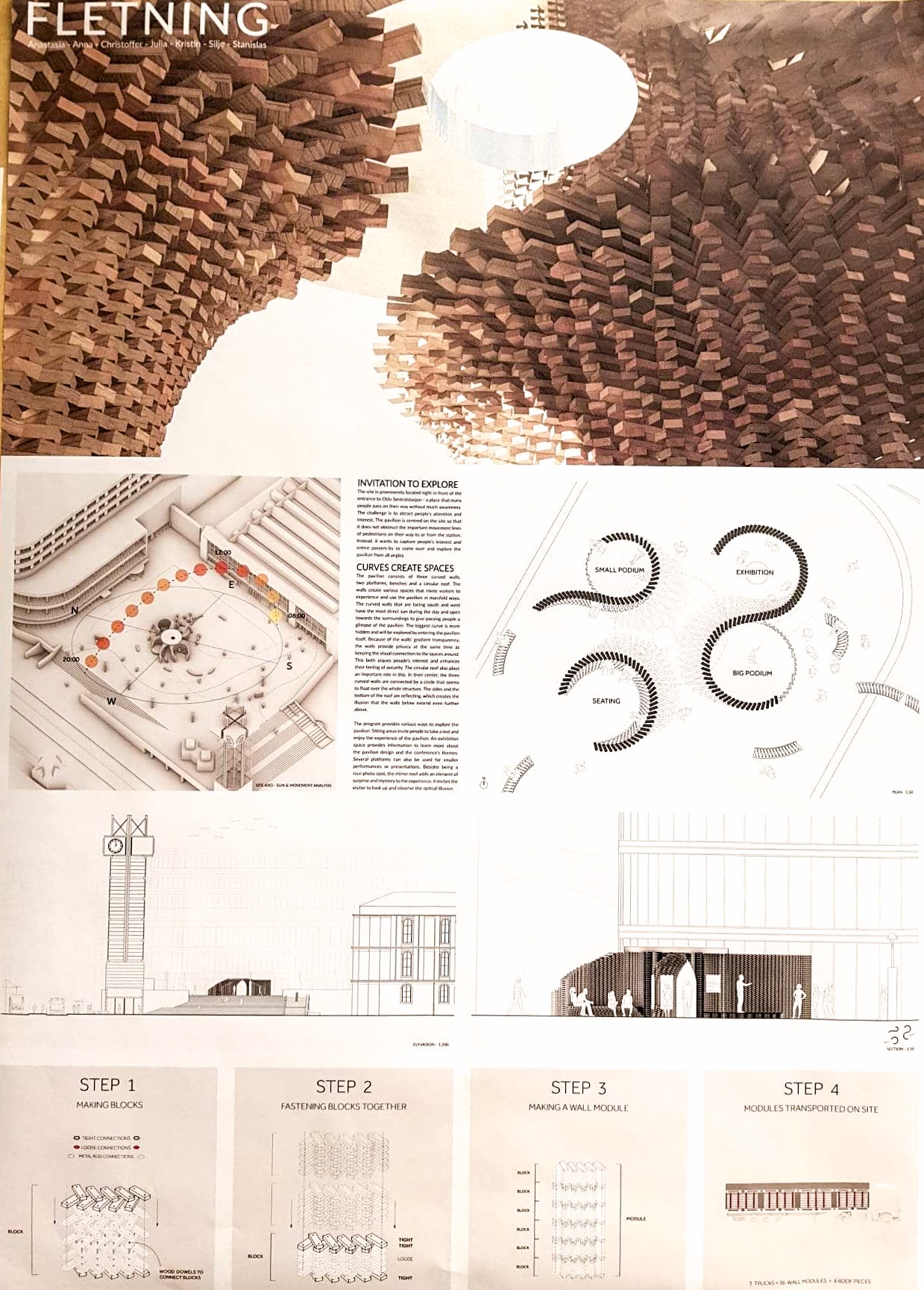

In varying group constellations, 10 initial ideas turned into 6 pavilion concepts, three of which have been developed into final projects. One of the students’ final designs “Fletning” is realised. “Fletning” means weaving in Norwegian.

The ambition of the pavilion project Fletning was twofold: to create organic shapes with highly standardized industrialized wooden parts, and to mainly use short dimensions that constitute a big part of timber waste and cut-offs.

On behalf of the WCTE organization, our platinum sponsor engineering company SWECO has been the project manager for the implementation of the pavilion as it stands in front of the Oslo Central Station. Collaborators on the pavilion include teachers at AHO, the gold and silver sponsors Aanesland Treindustri and Bergene Holm, as well the SirkTre Cluster and Oslo Municipality. The WCTE pavilion is funded by Innovation Norway.

After it’s installation in the City of Oslo, the pavilion will be disassembled, and the parts will have a subsequent life at a new location.

During the processing of wood into standardized industrial building materials, wood loses one of its original qualities, namely the organic shapes of the tree and its parts. The ambition of the pavilion project Fletning was twofold: to create organic shapes with highly standardized industrialized wooden parts, and to mainly use short dimensions that constitute a big part of timber waste and cut-offs.

Fletning” means weaving in Norwegian. Semi-transparent walls are created by stacking rows of short, offset 2’x4’ pieces (“wood bricks”) with altering angles. They allow glimpses through the construction that vary with every step as you pass by. Towards the wall’s top, the pieces gradually increase in length. In some places, where two adjoining cantilevering walls almost touch at the top, they form an archway. The walls’ curved geometry both ensures stability and creates subspaces for smaller exhibition sections, sitting areas or a podium. The structure’s geometry has been studied in a digital parametric model for full flexibility in the form-finding process. In order to compensate for the laterally projecting walls’ lack of weight, the students suggested a disk-shaped roof element that is filled with earth for weighing down the pavilion against wind forces. It is clad with disused offprint metal sheets that mirror the construction and visually continue the pavilion’s central space. In the realized design, the roof plate is omitted, and sandbagshidden in the two podiums add extra weight instead. The wood brick layers are connected by long oak wood dowelsand held together with steel rods. The pavilion has been prefabricated off-site in segments that fit on a truck.

As a contribution to The World Conference on Timber Engineering 2023 taking place in Oslo from 19.-22. June, AHO exhibits the results of two master studio courses that have investigated the design potential of waste materials. Welcome to the opening on June 18th at 16:00 at AHO’s byggehall!